Updated 4 months ago

Types of solar panels: monocrystalline, polycrystalline, and thin-film

Written by Catherine Lane Catherine LaneCatherine has been researching and reporting on the solar industry for five years and is the Written Content Manager at SolarReviews. She leads a dyna...Learn more

Why you can trust SolarReviews

SolarReviews is the leading American website for solar panel reviews and solar panel installation companies. Our industry experts have a combined three decades of solar experience and maintain editorial independence for their reviews. No company can pay to alter the reviews or review scores shown on our site. Learn more about SolarReviews and how we make money.

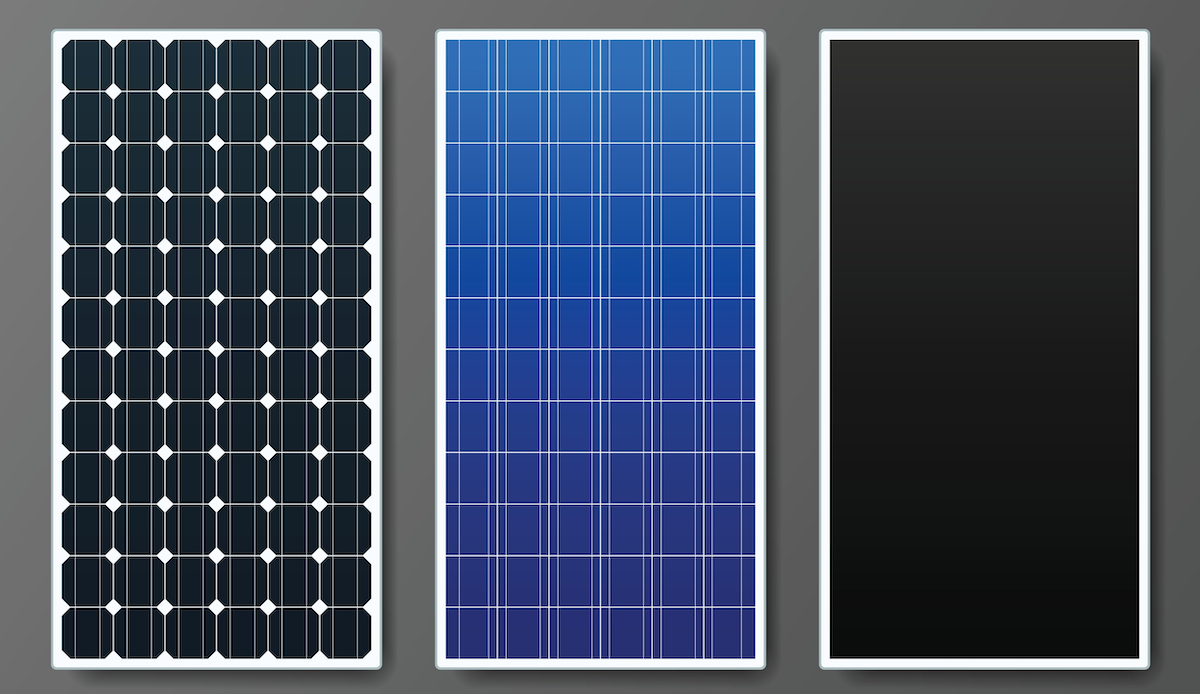

There are three main types of solar panels used in solar projects: monocrystalline, polycrystalline, and thin-film.

Each kind of solar panel has different characteristics, thus making certain panels more suitable for different types of solar installations.

Luckily, we’ve created a complete guide to help you differentiate each type of panel, and help you decide which type is right for your home.

Key takeaways

There are three different types of solar panels: monocrystalline, polycrystalline, and thin film.

All of the best solar panels currently on the market use monocrystalline solar cells because they are highly efficient and have a sleek design, but come at a higher price point than other solar panels.

Polycrystalline solar panels are cheaper than monocrystalline panels, however, they are less efficient and aren’t as aesthetically pleasing.

Thin film solar panels are the cheapest, but have the lowest efficiency rating and require a lot of space to meet your energy needs.

The brand of solar panels and the solar installer you choose is far more important than which type of solar panel you install.

Three types of solar panels

1. Monocrystalline

Monocrystalline solar panels are the most popular solar panels used in rooftop solar panel installations today.

Monocrystalline silicon solar cells are manufactured using something called the Czochralski method, in which a ‘seed’ crystal of silicon is placed into a molten vat of pure silicon at a high temperature.

This process forms a single silicon crystal, called an ingot, that is sliced into thin silicon wafers which are then used in the solar modules.

There is more than one type of monocrystalline solar panel!

Nowadays, there are several varieties of monocrystalline solar panels on the market to choose from. Passivated Emitter and Rear Contact cells, more commonly referred to as PERC cells, are becoming an increasingly popular monocrystalline option. PERC cells go through a different manufacturing and assembly process that increases the amount of electricity the cells can produce.

Bifacial solar panels, another monocrystalline technology, can generate electricity on both the front and back side of a module and are gaining traction in commercial ground-mounted applications.

2. Polycrystalline

Polycrystalline panels, sometimes referred to as ‘multicrystalline panels’, are popular among homeowners looking to install solar panels on a budget.

Similar to monocrystalline panels, polycrystalline panels are made of silicon solar cells. However, the cooling process is different, which causes multiple crystals to form, as opposed to one.

Polycrystalline panels used on residential homes usually contain 60 solar cells.

3. Thin-film

Thin film solar cells are mostly used in large-scale industrial and utility solar installations because of their lower efficiency ratings, but you can purchase portable thin-film solar panels from BougeRV.

Thin film solar panels are made by depositing a thin layer of a photovoltaic substance onto a solid surface, like glass. Some of these photovoltaic substances include Amorphous silicon (a-Si), copper indium gallium selenide (CIGS), and cadmium telluride (CdTe). Each of these materials creates a different ‘type’ of solar panel, however, they all fall under the thin film solar cell umbrella.

During the manufacturing process, the photovoltaic substance forms a thin lightweight sheet that is, in some cases, flexible.

Solar panel type by performance

Highest performance: Monocrystalline

Efficiency ratings of monocrystalline solar panels range from 17% to 22%, earning them the title of the most efficient solar panel type. The higher efficiency rating of monocrystalline panels makes them ideal for homes with limited roof space, as you’ll need fewer panels to generate the electricity you need.

Monocrystalline solar panels have their manufacturing process to thank for being so efficient. Because monocrystalline solar cells are made of a single crystal of silicon, electrons are able to easily flow throughout the cell, increasing overall efficiency.

Not only do monocrystalline panels have the highest efficiency ratings, they typically also have the highest power capacity ratings, as well. Most monocrystalline panels on the market today will have a power output rating of at least 320 watts, but can go up to around 375 watts or higher!

Mid-tier performance: Polycrystalline

Polycrystalline panel efficiency ratings will typically range from 15% to 17%. The lower efficiency ratings are due to how electrons move through the solar cell. Because polycrystalline cells contain multiple silicon cells, the electrons cannot move as easily and as a result, decrease the efficiency of the panel.

The lower efficiency of polycrystalline panels also means they tend to have a lower power output than monocrystalline panels, usually ranging between 240 watts and 300 watts. 300 watt solar panels aren't seen as often in residential applications, but some polycrystalline panels have power ratings above 300 watts.

However, new technologies and manufacturing processes have given the efficiency and power ratings of polycrystalline panels a slight boost over the years, slowly closing the performance gap between mono and polycrystalline panels.

Lowest performance: Thin-film

Thin-film solar panels have incredibly low efficiency ratings. As recently as a few years ago, thin-film efficiencies were in the single digits. Researchers have recently achieved 23.4% efficiency with thin film cell prototypes but thin-film panels that are commercially available generally have efficiency in the 10–13% range.

In order to meet your energy needs, you would need to install more thin-film panels over a large area to produce the same amount of electricity as crystalline silicon solar panels. This is why thin-film solar panels don’t really make sense for residential installations where space is limited.

Fun fact! Thin film panels have excellent temperature coefficients!

Despite having lower performance specs in most other categories, thin film panels tend to have the lowest temperature coefficient, which means as the temperature of a solar panel increases, the panel produces less electricity. The temperature coefficient tells you how much the power output will decrease by for every 1°C over 25°C the panel gets.

The standard temperature coefficient for mono and polycrystalline panels typically falls somewhere between -0.3% and -0.5% per °C. Thin film panels, on the other hand, are around -0.2% per °C, meaning thin film panels are much better at handling the heat than other panel types.

Solar panel type by cost

Highest cost: Monocrystalline panels

Monocrystalline panels are the most expensive of the three types of solar panels because of their manufacturing process and higher performance abilities.

However, as manufacturing processes and solar panel technology in general has improved, the price difference between monocrystalline and polycrystalline panels has shrunk considerably. According to the Lawrence Berkeley National Laboratory, monocrystalline solar panels now sell for just about $0.05 per watt higher than polycrystalline modules.

Mid-cost: Polycrystalline panels

Historically, polycrystalline panels have been the cheapest option for homeowners going solar, without majorly sacrificing panel performance. Low prices allowed polycrystalline panels to make up a significant market share in residential solar installations between 2012 and 2016.

But as we said earlier, the price gap between monocrystalline and polycrystalline panels is narrowing. Now, more homeowners are willing to pay a slightly higher price to get significantly better efficiency and power ratings from monocrystalline panels.

Lowest cost: Thin-film panels

Thin film solar panels have the lowest cost of the solar panel types, largely because they are easier to install and require less equipment. However, they also have much lower performance abilities and require a substantial amount of space to generate enough electricity to power a home.

Plus, thin film panels degrade much faster than other panel types, meaning they need to be replaced more often, which leads to more long-term recurring costs.

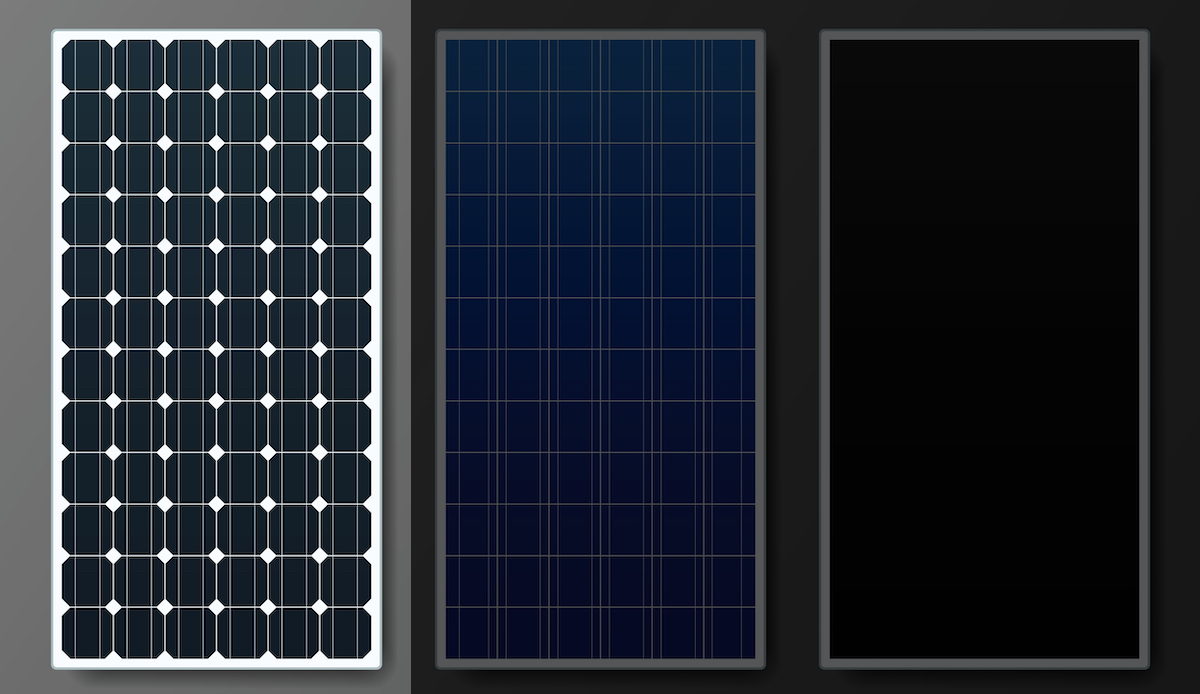

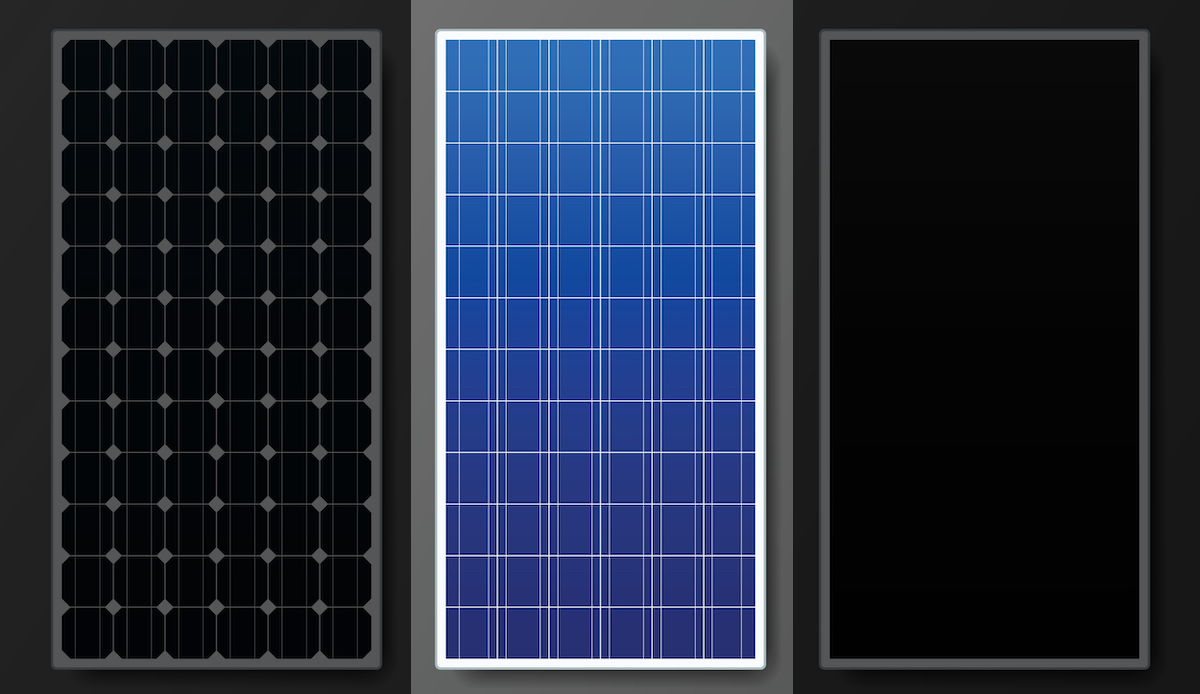

Solar panel type by appearance

Most attractive: Thin film panels

Thin film panels have a clean, all-black look. Their thin design allows them to lie flat against roofs, so they are able to blend in more seamlessly. In fact, with some thin film panels, it’s hard to even see the individual cells within the panel. They also tend to have less wiring and busbars, meaning there’s less white space.

However, because they are so inefficient, you would need to cover your entire roof in thin film panels - which may or may not be your style.

Mid-tier appearance: Monocrystalline panels

Monocrystalline panels have a solid black appearance, making them pretty subtle on your roof. But, the way monocrystalline solar cells are shaped causes there to be quite a bit of white space on the panel. Some manufacturers have worked around this with black packing or shaping the cells differently, but these aesthetic changes can impact both the price and performance of the panels.

Overall, monocrystalline panels still look sleek, but they’re a bit more pronounced than thin film panels.

Worst appearance: Polycrystalline panels

Polycrystalline panels tend to stick out like a sore thumb. The process in which polycrystalline solar cells are manufactured causes the cells to have a blue, marbled look. This means each individual polycrystalline panel looks substantially different from the one next to it. Most homeowners aren’t too keen on the aesthetics of polycrystalline panels.

Fun fact! Crystalline panels are more durable than thin film

Thin film panels tend to have lower wind and hail ratings than mono and polycrystalline panels. So, while thin film panels might look nice at first, one bad storm could cause significant damage.

What is the right type of solar panel for your home?

Monocrystalline solar panels are the best solar panels for residential solar installations.

Although you will be paying a slightly higher price, you’ll get a system with a subtle appearance without having to sacrifice performance or durability. Plus, the high efficiency and power output ratings you get with monocrystalline panels can provide you with better savings over the lifetime of your system.

If you’re on a tight budget, polycrystalline panels might make more sense for you. We do not recommend thin film solar panels for residential installations - their performance and durability don’t make the low cost worth it, and it’s unlikely you’ll have nearly enough space to install the number of thin film panels you would need to cover your household electricity usage.

Here’s a quick summary to help you choose the right one for your home!

Monocrystalline solar panels

Characterized by smooth, black appearance and high-quality silicon

Occupy less space and have a longer lifespan

Formed through energy-intensive production process which generates a lot of waste

Carry a higher price tag for installers and consumers

Polycrystalline solar panels

Characterized by visible crystals, more scattered look, and lower-quality silicon

Require slightly more space for producing the same amount of energy as black panels

Less complicated production process with minimal waste production

More affordable

Factors to consider besides solar panel type

There are two things we here at SolarReviews think are more important than solar PV cell type when choosing panels for your home: the brand of solar panels and finding the right solar installer.

Going with a high-quality solar panel manufacturer ensures that you’re installing a great product on your roof, regardless of the type of panel it is. Our official ranking of the best home solar panel brands can help you find which solar panels will work on your roof without sacrificing quality.

Regardless of which type of solar panel you choose, installing solar to power your home is a sustainable decision that has the following benefits:

Reduces harmful emissions

Get easy financing options for solar panel installation

Claim sales and property tax exemptions

And the most important of all, installing either type of panel will significantly lower your monthly energy bills.

Perhaps the most important thing to consider when going solar is the installer. A solar panel system will be on your roof for at least 25 years, so you need an installer you can trust for two-plus decades! We recommend local, reputable solar installers with high customer review scores, as they give the most personalized customer service on solar projects.

Catherine has been researching and reporting on the solar industry for five years and is the Written Content Manager at SolarReviews. She leads a dynamic team in producing informative and engaging content on residential solar to help homeowners make informed decisions about investing in solar panels. Catherine’s expertise has garnered attention from leading industry publications, with her work being featured in Solar Today Magazine and Solar ...

Learn more about Catherine Lane